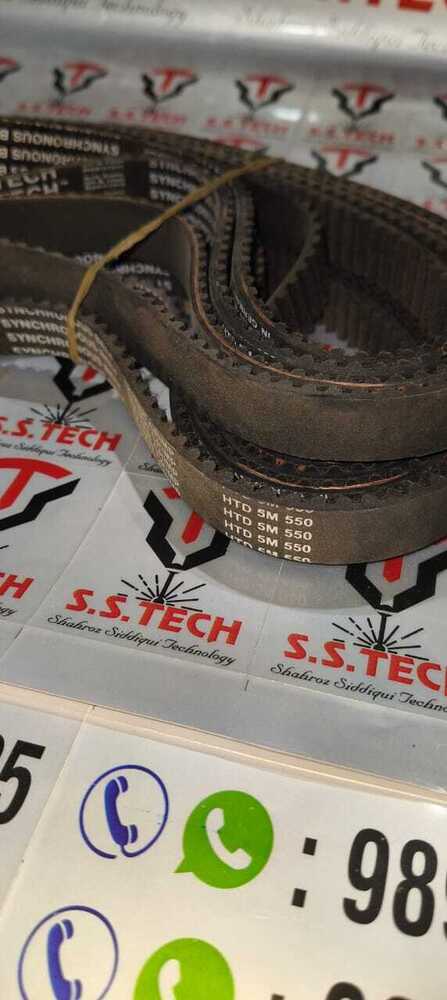

About 5m 550 Timing belt

Timing Belt: Precise Synchronization Overview A timing belt, also known as a synchronous belt or toothed belt, is a mechanical component used to transmit rotational motion between two or more pulleys. It ensures precise synchronization and timing in various applications. Key Features 1. Toothed profile: Ensures positive engagement and prevents slipping.2. High-precision timing: Maintains accurate synchronization.3. Low noise and vibration: Smooth operation.4. High torque capacity: Supports heavy loads.5. Resistance to wear: Long lifespan. Benefits 1. Improved accuracy: Precise timing and synchronization.2. Increased efficiency: Reduced energy consumption.3. Reliability: Long lifespan and low maintenance.4. Quiet operation: Reduced noise pollution.5. Cost-effective: Reduced replacement costs. Applications 1. Automotive engines (camshaft and crankshaft)2. Industrial machinery (textile, printing, and packaging)3. Robotics4. CNC machines5. Medical equipment6. Aerospace7. Conveyor systems8. 3D printers Types 1. HTD (High Torque Drive): High-torque capacity.2. STD (Standard Torque Drive): General-purpose.3. GT (Gates Tooth): High-precision timing.4. AT (Anti-Backlash Tooth): Eliminates backlash.5. Neoprene and Polyurethane: Different materials for various applications. Technical Specifications 1. Pitch: 2-50 mm (0.08-1.97 in).2. Width: 5-100 mm (0.2-3.94 in).3. Length: Up to 10 meters (32.8 ft).4. Material: Rubber, polyurethane, or neoprene.5. Operating temperature: -20C to 80C (-4F to 176F).

FAQs of 5m 550 Timing belt:

Q: What is the material used in the 5m 550 Timing belt?

A: The 5m 550 Timing belt is made of plastic.

Q: What color is the 5m 550 Timing belt?

A: The 5m 550 Timing belt comes in black color.

Q: What shape does the 5m 550 Timing belt have?

A: The 5m 550 Timing belt has a round shape.

Q: Does the 5m 550 Timing belt have any special features?

A: Yes, the 5m 550 Timing belt features durable polishing.

Q: Is the size of the 5m 550 Timing belt standard?

A: Yes, the 5m 550 Timing belt is of standard size.